Your requirements, Our solutions

Zumeks -Machinery Supplier and Engineering Company

About Us

1111At Zumeks, we are more than just a machinery export company – we are a dedicated team of experts driven by a passion for precision engineering. With a rich heritage and decades of experience in the industry, we have built a reputation for excellence and reliability.

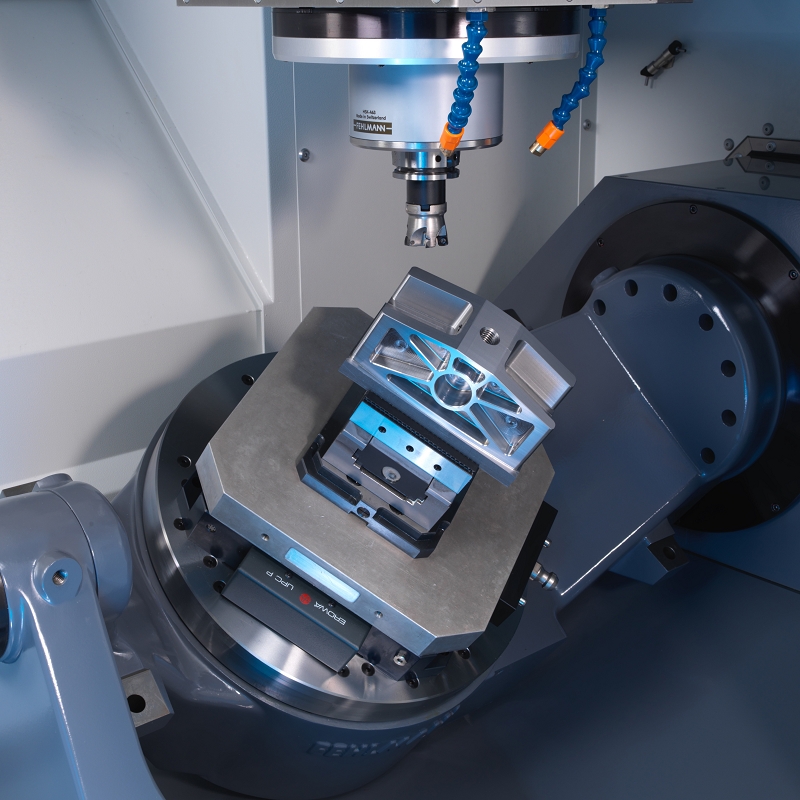

Our mission is simple: to deliver high-quality machinery and equipment to businesses around the world. We take pride in providing cutting-edge solutions that empower manufacturers, from CNC technologies to precision grinding and lathe machinery.

Proudly Serving All Brands

We are an engineering and trading company in Turkey and we also represent well-known machine tool manufacturers.

Our Services

Zumeks Engineering specialises in providing high-quality, cost-effective 3D tech solutions to businesses and individuals worldwide. Our state-of-the-art technology and experienced team of engineers and designers ensure that every project is completed to the highest standards of quality and precision.

Frequently Asked Questions

We offer customized solutions to help your business grow and achieve its goals. We not only care about your business, but also your dreams. That’s why we do our best to work together and turn your ideas into reality.

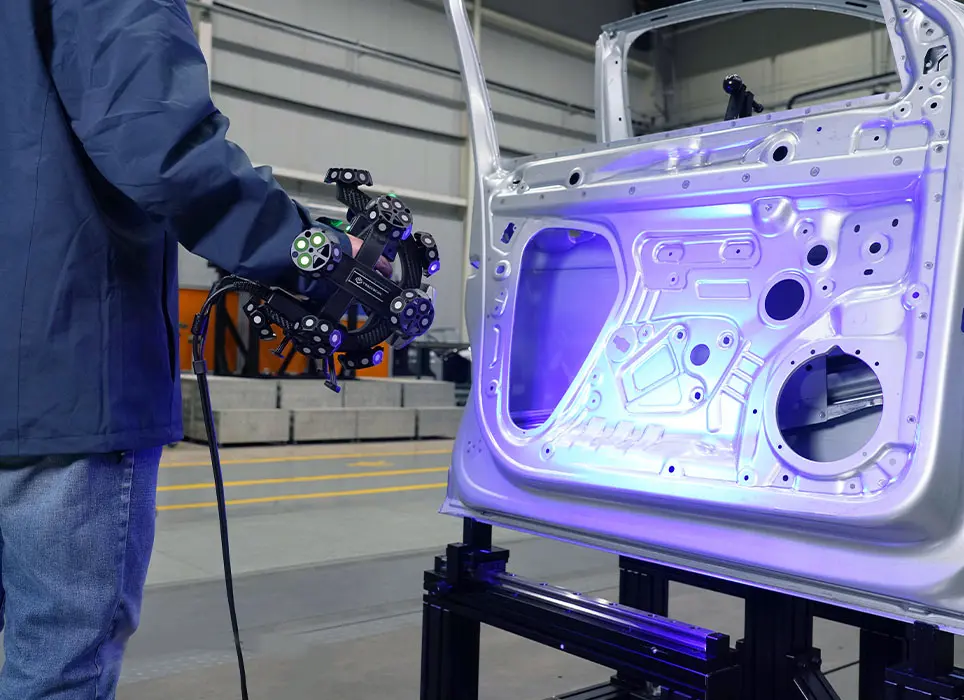

3D Quality Control and Reporting using 3D measurement systems (optical scanning system, laser scanning system, probe arms, coordinate measurement systems (CMM) etc.) is the evaluation of the measurements of manufactured parts.

3D measurement is the presentation of the coordinates and measurements of an object in space in the closest way to reality by various techniques. With these techniques, sometimes the coordinates of the main points can be made by measuring the surface of the whole object with certain frequencies. These techniques are determined according to the required report.

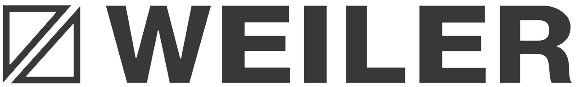

The systems that we call optical scanners in 3D scanning devices are also referred to as white light scanner systems. However, with the technology developing recently, light sources working with different colors and different technologies are preferred instead of white light. For example; white, blue red and green light technology is used.

Laser Scanning Laser scanning devices work with the technology of projecting a laser source onto the part surface and digitizing it with a camera. Laser scanning devices work with the technology of projecting a laser source onto the part surface and digitizing it with a camera. These are 6-7 axis arms, coordinate measuring looms (CMM) or hand terminals with infrared sensors on them.

CMM, known as the coordinate measurement system, measures according to the Cartesian coordinate. X, Y and Z axis moving the head of the system connected to the probe rotates 360 degrees in its own axis offers versatile measurement. With computer control, the head is automatically routed and the dot is automatically taken when it touches the part. Dimensional measurements are made by creating geometries with the obtained points. It is possible to measure with and without CAD data.

To provide value-added engineering services using 3D technologies.

Please feel free to contact us if you need any further information.